News

The Yarn Tree's owner, Linda LaBelle, is Featured in Cultivate Magazine Spring 2021 May 11, 2021 14:55

Indigo grows in Southwest Virginia!Color Ashram - Story of Indigo Part 4 - Indigo Masters April 24, 2020 08:45

Thank you Color Ashram for creating this beautiful video. I am honored to share this space with Gasali Adeyemo!

Back from India! March 7, 2020 15:40

I have returned home from India with lots of beautiful handwoven and hand-dyed scarves and some fabrics as well.Traveling to India January 20, 2020 08:29

I will be traveling to India in February 2020 and while I am gone you will be able to place orders - BUT - no orders will be shipped while I am out of the country.

Last day to place an order for shipping before I go will be Friday, February 14th. Shipping will resume on March 2nd.

Aranya Natural is celebrating its Silver Jubilee!!!

Aranya Natural was created 25 years ago – it was a dream, a wish, a thought. 25 years later Aranya Natural is world-renowned for both its natural dye work and the folks who are the heart of Aranya Natural - the artisans.

This event will take place on February 22,23,24,25 2020 in Munnar, Kerala, Southern India.

Registration for the conference is open on their website HERE

The workshops are sold out!

There will be a 2-day conference with some very knowledgeable speakers and there will be 2-days of workshops.

I will be teaching 2 workshops along with Michel Garcia, Buaisou and Jagada Rajappa

Located in Kannan Devan hills, Aranya Natural is part of the larger Srishti Trust, a welfare center for the differently-abled. There are five arms to this organization and you can read more on their website HERE

Munnar is located in an area with lush greenery, rolling hills covered in teas bushes, friendly people and great food. Here the air is fresh, the atmosphere soothing and Ayurvedic Spas will relieve your jetlag.

Come celebrate with me! Meet the folks responsible for making this dream a reality and meet the artisans who make the magic happen!

I hope to see you in Munnar in February 2020!

Very Exciting News! September 21, 2019 08:43

I am completely over the moon!! My indigo garment has been accepted for an exhibition in Tokushima, Japan!

The piece is titled Blueness/Oneness. The inspiration came from many places. A coming together - a celebration - of many cultures!

It’s All About Red! September 13, 2019 12:54

I am often asked “what is your favorite natural dye?” – besides indigo. That is hard to answer – I love them all.

One of my favorites though is Cochineal (Dactylopius coccus), a scale insect that produces Carminic Acid, known as Natural Red 4, or Carmine, it is used to color textiles, foods and cosmetics. It is my understanding that the insect ingests the juices of the Nopal cactus (its host) these ingested juices then mix with the insect’s stomach acid to produce carminic acid.

It's All About Madder! September 9, 2019 04:28

Let's talk about Madder - Rubia tinctorum - the root that gives us peachy pink to orange to true red!

Exciting News! August 8, 2019 14:51

Have you ever wanted to visit India, spend time in a region steeped in natural beauty, explore natural dyes and right before your eyes see how dreams really do come true?

Aranya Natural was created 25 years ago – it was a dream, a wish, a thought. 25 years later Aranya Natural is world renowned for both its natural dye work and the folks who are the heart of Aranya Natural - the artisans.

February 22, 23, 24 and 25, 2020 is when this event will take place in Munnar, Kerala, Southern India.

Registration is open on their website https://www.aranyanatural.com/

More information will follow.

But I will let you in on a little secret – I will be teaching two ½ day, four-hour indigo related workshops on the 24th & 25th.

Located in Kannan Devan hills, Aranya Natural is part of the larger Sristhi Trust, a welfare center for the differently-abled. There are five arms to this organization and you can read more on their website http://www.srishtinatural.com/

Munnar is located in an area with lush greenery, rolling hills covered in teas bushes, friendly people and great food. Here the air is fresh, the atmosphere soothing and Ayurvedic Spas will relieve your jet-lag.

Munnar is situated in the Western Ghats in the state of Kerala. Eravikulam National Park is just a short Tuktuk ride away. Here you will see amazing views, beautiful wild flowers and the endangered mountain goat Nilgiri tahr.

Come celebrate with me! Meet the folks responsible for making this dream a reality and meet the artisans who make the magic happen!

I hope to see you in Munnar in February 2020!

Weave - Podcast: WIth Linda LaBelle August 8, 2019 07:16

Episode 72: A Natural Dye Journey Across The Globe With Linda LaBelle

This week on the podcast, LaChaun is talking with Linda LaBelle is the owner of The Yarn Tree, a teacher, entrepreneur, author, photographer and; career fiber artist specializing in natural dyeing and weaving. In their conversation we talk about Linda’s dye garden as well as her many trips across the world to learn, teach and gather dye materials to share with the natural fiber community.

farmers and mill owners, textile artists and loom manufacturers,

to tell the stories of the threads that bind us together.

The podcast is hosted by Sarah Resnick and LaChaun Moore.

It's All About the Mordants and Assists March 10, 2019 11:34

Mordants and Assists available at The Yarn Tree

Today I’d like to talk about mordants.

The word mordant comes from the French word “mordre” – to bite. The mordant combines with a natural dye and fixes the color to the material. Mordants make the color richer, lightfast and wash-fast. Using the right mordant is like cooking you would never substitute salt for sugar! The following 3 mordants are the refined state of Bauxite (the raw state of aluminum ore).

Alum (Potassium aluminum sulfate) – Alum is probably the most commonly used non-toxic mordant and can be used with both protein and cellulose fibers. It is economical. Dyers often will add Cream of Tartar to obtain brighter colors. Aluminum Acetate is a highly refined version of Alum and therefore more expensive. It is the ideal mordant for cellulose and is often combined with a clear tannin for even better results. Aluminum sulfate is Alum without the Potassium and the amount needed for good results is lower than Alum. It also will give brighter colors without the need for Cream of Tartar. Our final mordant is Titanium oxalate. Titanium oxalate has been used for tanning leather, and is growing in popularity with natural dyers. It can give shades of orange in combination with tannins and yellows.

When working with mordants we recommend the use of gloves and masks.

Here are 6 natural dye assists that I like to call color changers.

1-Chalk (Calcium Carbonate) – is used as a color changer. If you have “soft” water the addition of chalk to your dyebath will make your water “harder”. It is especially useful to make madder dye-baths redder.

2-Citric Acid – an organic acid with a pH of less than 7. It is used with Lac to bring out the strongest color. Acidic modifiers will make a more yellow tone (changing madder red to madder orange). Acidic modifiers can be used in the dyebath or as an after-bath.

3-Cream of Tartar – a by-product of wine making. It is an organic acid with a pH of less than 7. It is an optional addition to the Alum mordant bath. It will keep wool soft, brighten colors and change some dye colors (Cochineal will go from fuchsia to red with the use of Cream of Tartar). Cream of Tartar works best on protein fibers and is rarely used with plant fibers.

4-Iron (Ferrous Sulfate) – Iron is best for use with plant fibers. Iron can be used as part of the mordanting process, in the dye-bath or as an after-bath. Iron will deepen and sadden (grey) your colors and can change yellows to greens.

5-Soda Ash (Sodium Carbonate) – an alkaline modifier. Soda Ash increases the effectiveness of a mordant and can change colors dramatically (Brazilwood will go from red to pink). Soda Ash is also used in conjunction with a soap product to scour cellulose fibers.

6-Tartaric Acid - a by-product of wine making. It is an organic acid with a pH of less than 7. Recommended for wool and silk when mordanting with Alum. Tartaric acid will give different shades than Cream of Tartar. It is highly recommended when dyeing with Cochineal. Tartaric Acid works best on protein fibers and is rarely used with plant fibers.

Indigo assists - There are far too many ways to make an indigo vat to go into here. All over the world indigo vats are created differently – all with the same result – beautiful blue! I will briefly touch on a few of them that I work with here. Michel Garcia’s 1,2,3 vat uses 1 part indigo, 2 parts hydrated lime (Calcium hydroxide) and three parts either fructose crystalline or henna powder. The 1,2,3 ferrous vat uses 1 part indigo, 2 parts iron (Ferrous sulfate) and 3 parts hydrated lime (Calcium hydroxide). A natural ferment vat may use indigo, cooked bran, ground madder root and soda ash (Sodium carbonate). A chemical vat may use indigo, thiourea dioxide and soda ash (instead of Lye – Sodium hydroxide/Caustic soda). Hide glue is used when working with wool. It is hydrated and introduced into the indigo vat to protect the wool from the alkalinity of the vat. pH papers are an aid in determining the pH of your vat (acid, basic or neutral), which varies for protein and cellulose.

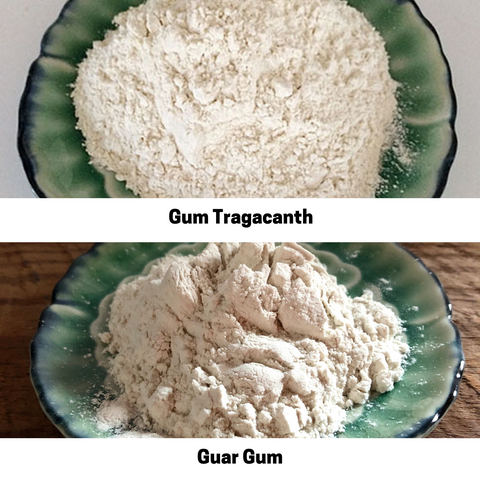

Natural Thickeners - Natural dye extracts can be thickened for painting, stamping and printing. 1) Gum tragacanth (Astragalus gummifier) works well with dye extracts and will not affect the color. It has been in use since ancient times and is still collected by hand. 2) Guar gum comes from (Cyamopsis tetragonolobus (L) Taub) is extracted from the Guar beans. Guar gum is a natural thickening, stabilizing and emulsifying agent used in the food industry as well as for other applications. It works well with dye extracts and will not affect the color.

Scours - It is important to properly scour (pre-wash your fiber, fabric or yarn prior to dyeing. 1) “Earthues Silkzorb Degummer is liquid enzyme that remove excess sericin in silk fibers, allowing for a deeper penetration of dye and deeper shades. Use with a small amount of soda ash and Earthues Cellulose Scour.” 2) “Earthues Cellulose Scour - is designed for use with cellulose fibers and as part of the Silkzorb degumming process. It works on cellulose and bast fibers in combination with soda ash and heat and thoroughly cleans cellulose fibers, removing excess wax and other materials which could inhibit the takeup of dye.” 3) “Synthrapol® is an industrial strength, pH neutral, liquid detergent used as a prewash and afterwash for dyed or painted fabrics." Synthrapol works well with both protein and cellulose fibers. Use with a small amount of Soda ash in the prewash for cotton and other cellulose fibers.

It's All About Color - Bugs, Plants and Extracts March 10, 2019 09:30

Natural Dyes available at The Yarn Tree

The Blues - Indigofera tinctoria from Southern India, Indigofera suffruticosa from Central America, Indigofera tinctoria from Living Blue in Bangladesh and European Woad

Indigo Kits - You can choose Ferrous, Fructose or Henna and you can select Indigofera Tinctoria or Indigofera Suffruticosa. Would you like a Woad kit? Just ask, we’ll put one together for you! The kits come with a full set of instructions for making, maintaining and reviving the vat

Here are some "clear tannins", tannins that give little color but play an important role. These 4 tannins impart little color and are used to aid in mordanting cotton along with Aluminum Acetate, they impart a wide range of grays with an iron after-bath and in conjunction with Titanium oxalate an array of oranges! So don’t overlook these quiet but important aids to your color palette!

Working with the actual plant material is so much fun and always makes my studio smell great! These are 4 plant dyes that produce different and beautiful lightfast yellows!

Here are four sustainably harvested woods that give a wide range of lightfast and wash-fast yellows. Over-dye with indigo for a wide range of greens.

Here’s a look at roots, nuts and fruit that give color. Madder root gives oranges to reds to purples. Kamala is the soft powder on the outside of the fruit and gives golden yellow to tangerine. Over-dye with indigo for forest green. And finally walnut hulls are high in tannin and produce butternut to umber and dark brown with an iron after-bath.

BUGS! The Cochineal insect lives on the Nopal Cactus. While they can be found in the wild, today most Cochineal is produced on farms in Mexico, Peru and the Canary Islands. The insect produces Carminic acid and the dye ranges from softest pinks to brilliant reds! Cochineal colors more than fibers - it colors food and beauty products as well.

Tannin can be found in roots, wood, bark, leaves, galls and the skin of certain fruits. These four are in extract form, all with a high rate of tannin and produce color. Cutch produces caramel to coffee brown, Chestnut produces parchment to elephant grey - over-dye with indigo for mallard green. Myrobalan produces butter yellow to grey green - over-dye with indigo for teal. And finally we have Pomegranate which produces gold to khaki - dip in an iron after-bath for moss green.

All four of these extracts have a high tannin content (30-60%) and produce color. Acacia (Wattle) produces ash rose to nutmeg. Persian Berries produces yellows and beautiful greens with an indigo over-dye. Quebracho wood is some of the hardest wood! Q-red produces peach to pink and Q-yellow produces yellow.

These 6 extracts are known for their color! Why extracts? When you use the actual plant matter it takes 100-200% WOG. When using extracts the percentage is much, much lower (2-15%). What I especially like about extracts is how easy it is to develop replicable color formulas (True Red – 15% madder extract + 2% Cochineal extract). Chlorophyllin produces apple green. Cochineal, the colors range from the softest pink to brilliant red. Lac - pink orchid to crimson to burgundy. Logwood produces purple to blue to grey to black. Madder gives us orange to brick red to purple. And finally, we have Weld giving us the clearest yellow and amazing greens when over-dyed with indigo.

Settling In! January 12, 2019 11:28

Roanoke is beginning to feel like home! I have been here for 2 months now. Still lots of work to do to get the studio set up and lots more boxes to unpack.

My 55 gallon indigo vat is bundled up against the cold. It is 60F in the studio but the vat is staying at a very comfortable 73F. And winter is the perfect time for experimenting.

As I winnow the indigo seeds I am eager for Spring and have been planning out the new indigo garden.

Now it is time to sit back and watch the snow fall!

Indigo Vat bundled up against the cold!

My Love Affair with Indigo February 26, 2018 08:51

My love affair with Indigo began many years ago. It was when working with silk dyes that I needed to find an alternative dye source as I began to have a bad reaction to the chemical dyes.

At about the same time, I moved to New Mexico where I had the opportunity to be exposed to natural dyes being used to dye yarns for the beautiful woolen rugs being produced there.

As I studied the plants of New Mexico, and learning their uses both for color and medicine, I began forming a long-term goal of working with natural dyes.

For many years I was a dabbler – experimenting, studying and reading about these fascinating dyes.

Fast forward to August 2001 when I opened The Yarn Tree, a retail store selling yarn, fiber and dyes and studio in Brooklyn, NY. I suddenly had space where I could begin dyeing on a larger scale. I began dyeing yarns to sell in my shop and eventually teaching workshops in natural dyeing. I can still remember my excitement (and nervousness) at working with my first indigo vat – this amazing and magical color that I had studied for so long. My first vats were chemical vats – using natural indigo with a combination of lye and thioureadioxide. These chemical vats gave great color and were not difficult to make but gave off a wretched odor.

Once again fate intervened – I had been living in a tiny rent controlled studio apartment for many years when a large apartment with an outdoor space came available near my store. That spring I set up my first natural ferment indigo vat. I believe it was 15 or 20 gallons in size. This was when I first began to think about the possibility of growing my own indigo but it would be years before I could do so. By the next spring I had taken on a second studio space that was to be my dye studio. Here I set up a 55 gallon natural ferment indigo vat that I kept alive for 5 years.

Unfortunately in 2011 I closed the business and left NYC as I could not recover from the 2008 recession.

I moved to the South, first to Asheville, North Carolina and eventually to Greenville, South Carolina and continued to work with, teach and sell indigo and indigo dyed products.

There is a history of indigo growing in South Carolina. It was first grown on a plantation run by a young woman, Eliza Pinckney, in 1740. She grew Indigofera tinctoria and it took three years before she had a successful crop. Indigo then became an important cash crop for the South until the American Revolutionary War!

Knowing that the climate here successfully hosted indigo growing I decided to finally pursue my long held dream of growing and using my own indigo.

I purchased Japanese Indigo seeds (Polygonum tinctorium aka Persicaria tinctoria) from Rowland Ricketts and got ready to plant.

My first planting was very small – an almost heart shaped spot on my front lawn where once had been a large tree since removed. I had a successful crop and used the fresh indigo leaves to dye silk scarves.

For year two I decided to expand and purchased the materials to make four raised beds each 42inches X 42inches. I set these up on my front lawn. Again I had a very good crop. The first harvest was used to do fresh leaf indigo dyeing and the second was grown for the seeds.

My next goal is to expand my growing area and I am hoping to get my hands on some Indigofera tinctoria seeds. I want to grow Indigofera tinctoria and make my own indigo cakes!

I have had the opportunity to teach indigo dyeing (and natural dyeing) in many parts of the world including two workshops at IndigoSutra in Kolkata this past November.

For me it was a natural progression to go from experimenter to dyer to grower.

But why this fascination with indigo?

I like to say that Indigo is as old as time, we know it has been in use for several thousand years. It is grown all over the world – just different species – Indigofera tinctoria, Indigofera suffruticosa, Indigofera guatemalensis, Persicaria tinctoria to name a few.

Each culture has their own method of going from green plant to dyestuff whether it be fresh leaf, balls, cakes, paste or sukumo. Each culture has its own way of making an indigo vat with their very own special and sometimes secret ingredients. Yet we all produce the same color – Indigo Blue. Each culture has great respect for indigo and most honor the Indigo god with offerings, altars and sacrifices. And indigo has many names Anil or Nil – thought to be after the Nile River, Indigo coming from the word India and in Japan it is known as Ai or Aizome.

Indigo is surrounded with both myth and superstition. In some cultures only women are the dyers and others only the men. It is a color worn by both peasants and royalty.

And it has medicinal properties. Here are several – an indigo dyed cloth wrapped around your forehead will alleviate a headache, wearing indigo clothing can be calming, it is a natural bug repellent and it can be used to reduce fevers.

Indigo commands respect. By this I mean that one cannot be in a bad mood or rushing when working with indigo – you will not have good results. You must be patient. Having a natural indigo vat is like caring for a child or a pet – it cannot get too cold or hot and must be fed. Well-maintained indigo vats will survive for years and years. It is said that there are 100 year-old indigo vats in Japan.

For me indigo is more than just the color blue, it is a way of life.

Linda LaBelle

Traveling to India in Search of Indigo! June 14, 2015 07:10

INDIGO SUTRA celebrates Indigo, the world's oldest, most widely used and unique dyestuff, and the only natural blue dye.

The increasing awareness of using organic products in a highly polluted world has led to the current desire to use sustainable indigo for clothing and other textiles. INDIGO SUTRA is a milestone project, using expertise and guidance of top scholars, academics and practitioners of indigo from across the world.

The event will focus on the production and use of natural indigo, with seminars, exhibitions, demonstrations, workshops, discussion forums, documentary film shows, sale of indigo based textile and other products.

IndigoSutra takes place in Kolkata, India on November 9, 10, 11, 12 2017

While there I will be teaching two workshops!